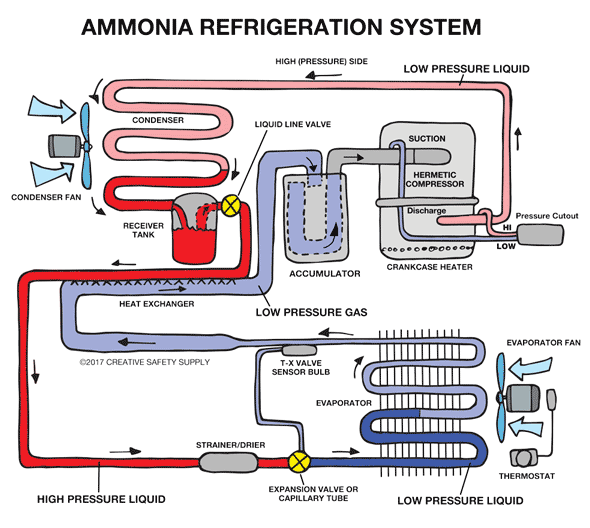

Thermostat and other control units of the cold storage room are properly set. It shows the elements of the circuit as streamlined shapes as well as the power and signal connections between the devices.

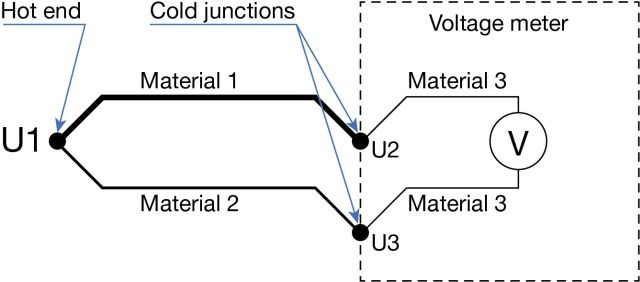

Thermocouple Cold Reference Junction Compensation

Cold room wiring diagram pdf. Project identification and construction signs. Evaporating unit only for complete cold room management. Cold room design guideline us guide. On initial operation or restart after a long time the crankcase heater should be energized for 6 hours prior to start up. And local codes 208230 vac 60 hz 3 ph. Complete the wiring with the push on connectors.

Ryb electrical 986298 views. 32 contactor and circuit breakers are mounted on trays in the control box. Air cooled condensers outdoors need head pressure control when. A wiring diagram is a streamlined traditional photographic representation of an electrical circuit. Cold room wiring diagram pdf wiring diagram is a simplified normal pictorial representation of an electrical circuit. Cold room ambient temperature range is 5c to 40c.

Ground equipment per nec. Required to operate in ambient temperatures below 60 f. Freezer room electrical diagram. Bk bl bl bl when used pri trans sec r bl g r bl t1 l1 cont. General components of cold rooms. T t3 compressor contactor l3 ladder diagram fan y rv rv rv coil cc c defrost control.

Cold room control panel freezer room duration. Word cool not cold. Three phase dol starter control overload indicator power wiring diagram duration. Cold room designguidelines free ebook download as pdf file pdf text file txt or read book online for free. 31 procedures and information required for wiring cold and freezer room are obtained and source in line with workplace procedures. Connection diagram o bl o bl attach ground ps2 ps1 lphp lphp two switch wiring r power supply per nec.

Oil level is at the designed limits. It shows the components of the circuit as simplified shapes and the power and signal contacts amongst the devices. 33 wiring is carried out in line with manufacturers specifications and workplace procedures. Front access to the automatic fuse and motor protector for the compressor and an innovative design combine to make it the ideal choice for effective refrigeration control. Applications complete management of three phase refrige rating systems up to 75 hp static or ventilated. It includes the entire panel ceiling panel and room panel which is made from import pipeline auto perfusion foaming import black material double side pressed colored steel panel with protective coating and the thickness is generally 100 mm 120 mm and 150 mm.

Variety of cold room control panel wiring diagram.