To change the ppr on tachs with three buttons follow the steps below. Our heavy duty electrical gauges are based on proprietary magna torque air core movement and compatible with.

Heavy Duty Industrial Gauges Maximatecc

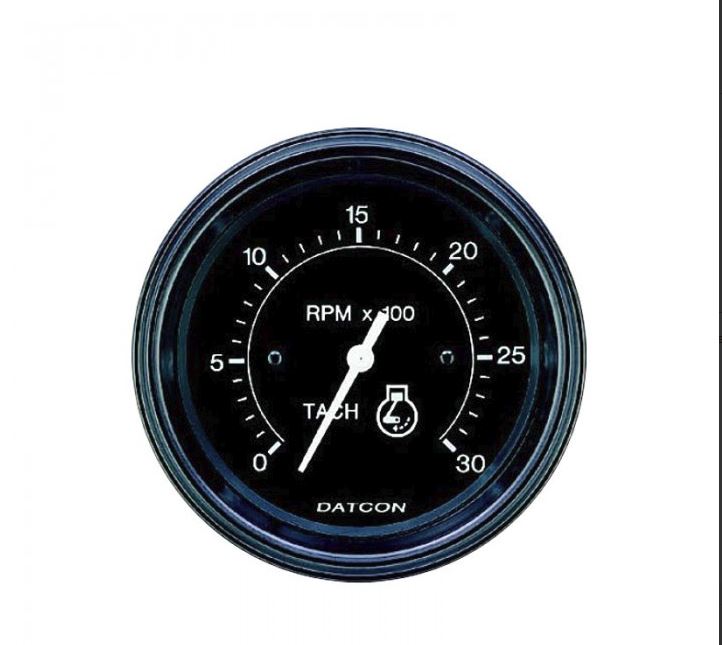

Datcon tachometer wiring diagram. Tachometer mg3000 smartcraft engines 2 mb owners manual. Datcon heavy duty industrial gauges the precise measure of performance datcon gauges by maximatecc are designed for severe duty off highway industrial and specialty vehicles used in the most environmentally mechanically and electronically challenging applications possible. Connect a wire from pin 5 to a constant 12 or 24 volt source. Apply power to the tach by turning the ignition key to the accessory or on position. Warranty information lighting information this product provides a two 2 year limited warranty all datcon tachometers and tachhourmeters have provisions for optional lighting. Access to the rear of the unit is required for calibration.

Refer to diagram d. Tachometer mg3000. The pointer will move to a. This article on how to wire an electronic tachometer doesnt have anything to do with project x other than that 57 is the granddaddy to super chevys chevelle. Datcon tachometer wiring diagram wiring diagram is a simplified up to standard pictorial representation of an electrical circuit. Its important to make sure youve got the correct wire for the tachometer which means you might need to use a multimeter with a tach setting to test the wires correctly and.

If lighting is desired the 24 volt kit must be installed. Follow this wire to a junction and attach the wire from pin 4 at this junction ie. Do not start the engine. C temperature there are two datcon match temperature senders typically the datcon high sender is 1000 ohms at 100f to 87 ohms at 220f while the datcon low sender is 450 ohms at 10of to 464 ohms at 220f. Connect the wire from pin 4 to a switched 12 volt or 24 volt source. All datcon tachometers and tachhourmeters will fit standard sae panel openings of 3 38 or tach mounting kit part no.

It is advised to connect the wiring and calibrate the unit before final mounting. Depending on your engine there may be a constant flow wire and a pulse wire to the tach as well as the additional wires for the ignition lights and other components. A switched 12 or 24 volt wire can be found coming from the ignition switch. With no power applied to the tach press and hold the set button. Tachometer 5 7000 rpm with trim and oil psi. The tachometer is configured at the factory for 4 ppr.

Tachometer mg3000 dual nmea2000 and j1939 engines. Tachometer mg3000 nmea and j1939 engines 2 mb owners manual. Precision speed troubleshooting industrial gauges meters sensors. It shows the components of the circuit as simplified shapes and the capacity and signal friends surrounded by the devices.