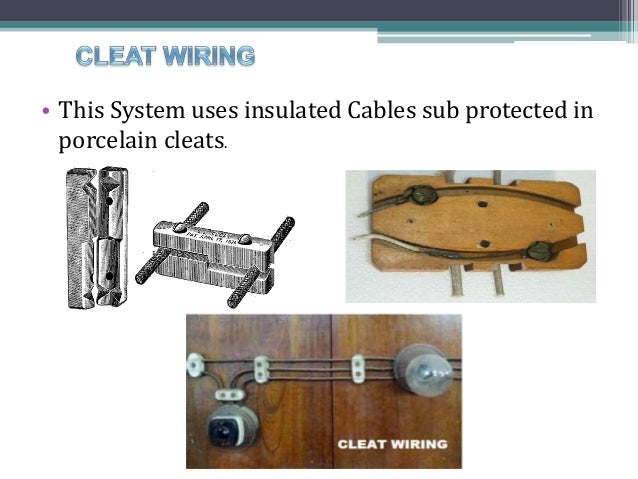

In cleat wiring vir pvc and weather proof sheathed cables are commonly used. The cleat wiring on insulators shall he installed in accordance to regulations.

Engineering A 500 Kv Underground System T Amp D World

Cleat wiring diagram. Cleat wiring casing wiring batten wiring conduit wiring concealed wiring. Porcelain cleats or plastic cleats two or three grooves screws. The wires can be weather proof. Work is first started from the ceiling rose or from the lamp bracket at the farthest point of the load circuit. What is type of circuit will be clear from table no. What is electrical wiringelectrical wiring is the electrical power distribution through the wires in a perfect manner for economic use of wiring conductors inside a room or building with better load control.

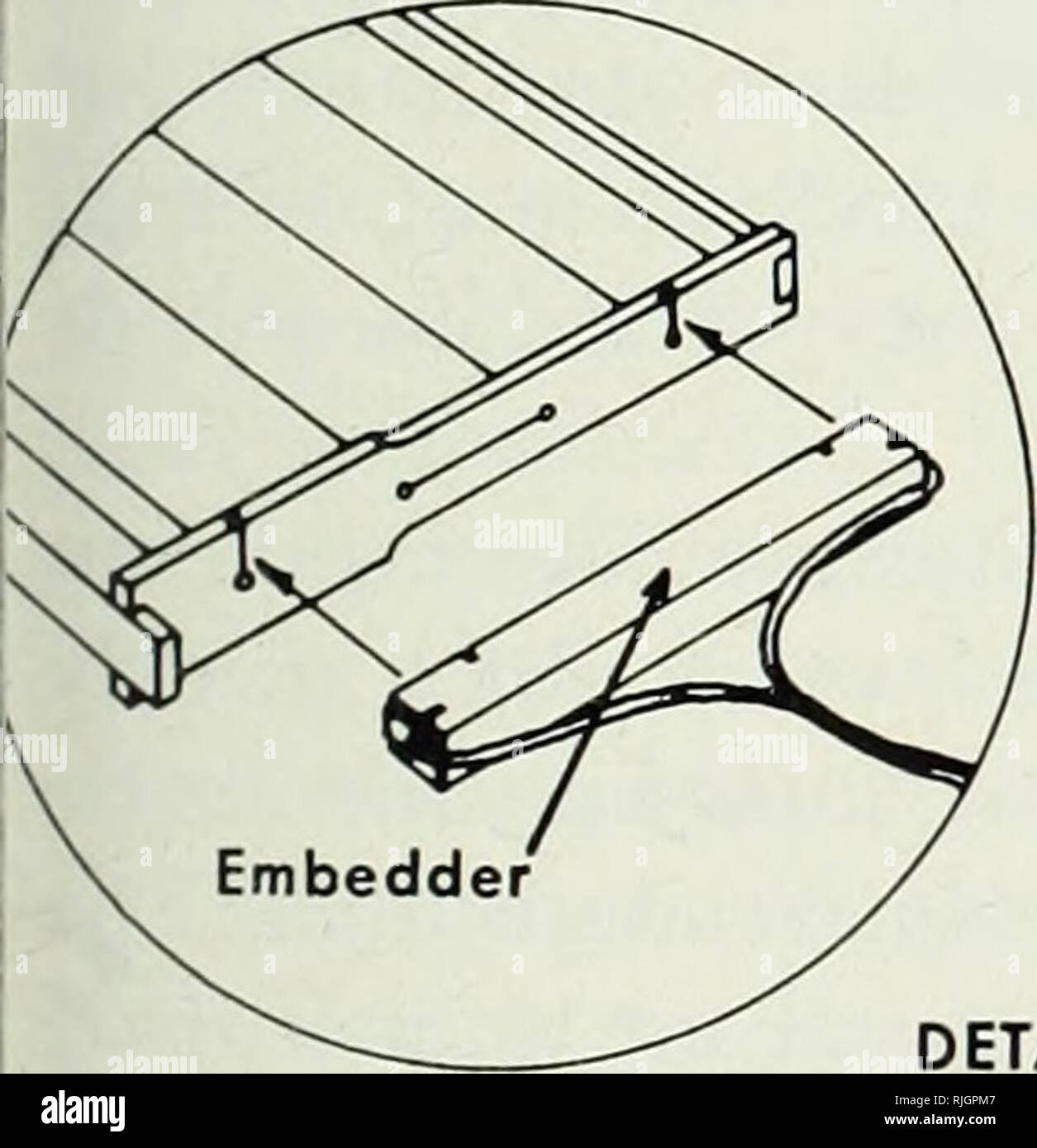

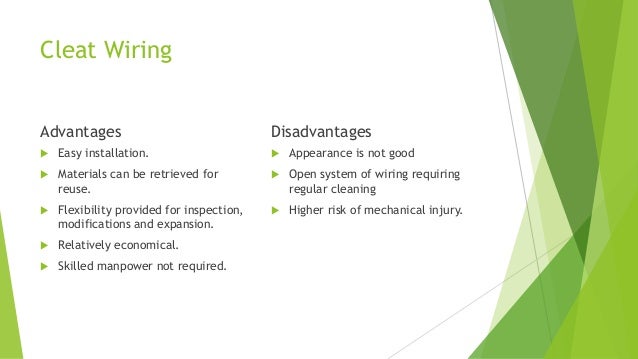

Spacing between wires in cleat wiring. Installation of cleat wiring. The electrical wiring diagram is a pictorial representation of the circuit which shows the wiring between the parts or elements or equipments. Customization can be easily done in this wiring system eg. Appearance is not so good. Procedure of cleat wiring in this wiring vir or pvc insulated wires are braided and compounded on walls or ceiling with the help of porcelain cleats.

It gives detailed information about wiring such that one can get an idea of making connection between the devices. The spacing between wires drawn through the cleats depends upon 1 line voltage and 2 type of circuit. The cleat has a two parts. Disadvantages of cleat wiring. Simple wire laying is done in this scheme of wiring. It is the oldest wiring method.

Cleat wiring system installation is easy and simple. It is permitted on systems up to 440v or 600v. Electrical wiring system is classified into five categories. Cleat wiring cant be use for permanent use because sag may be occur after sometime of the usage. Inspection is easy and simple. The insulators are made by porcelain plastic or hard wood.