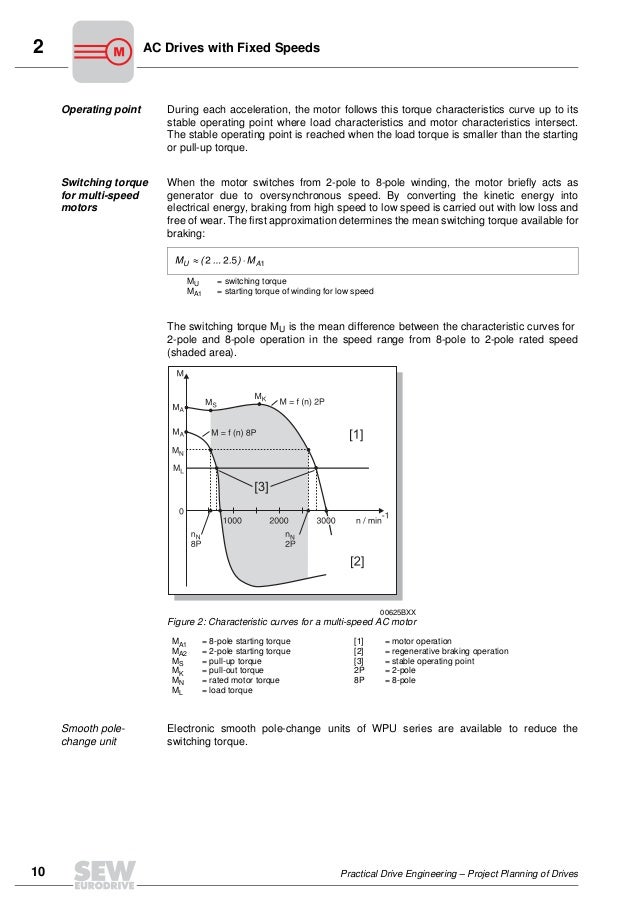

Fractional accelerator sew eurodrivedriving the world brake coil. When connecting the supply power from the motor terminal block to the brake rectifier follow the specifications below.

Brake Service And Maintenance

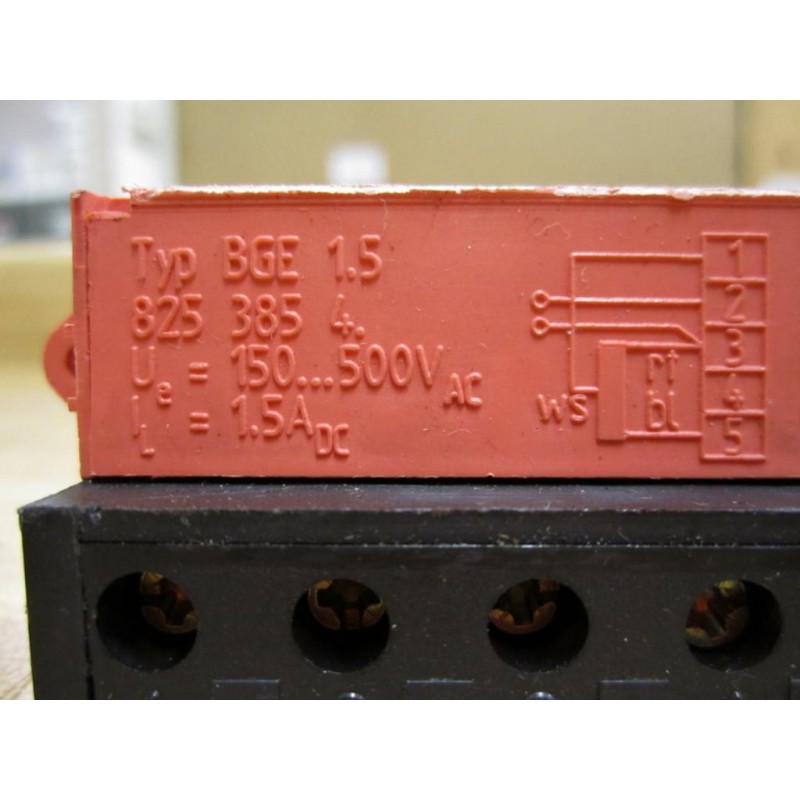

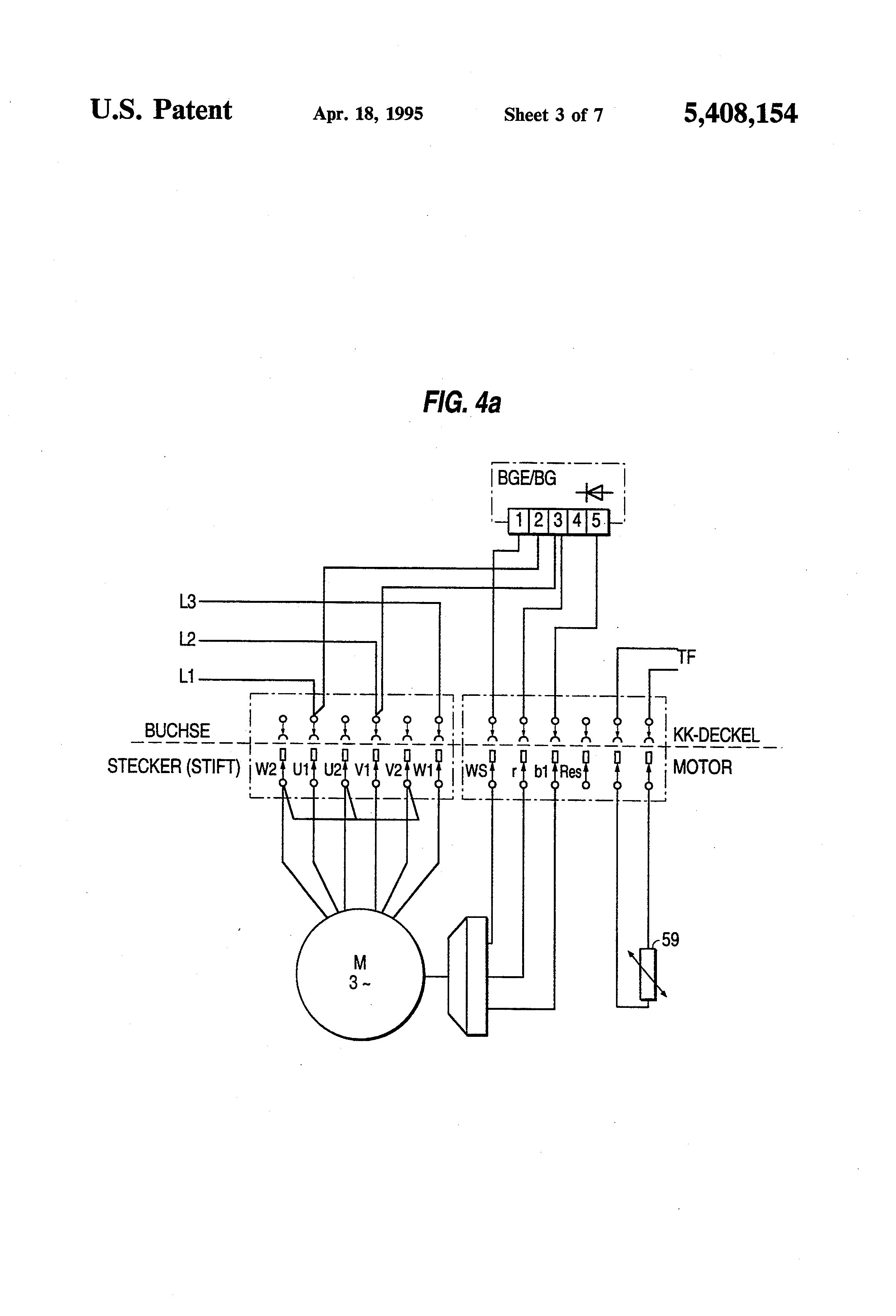

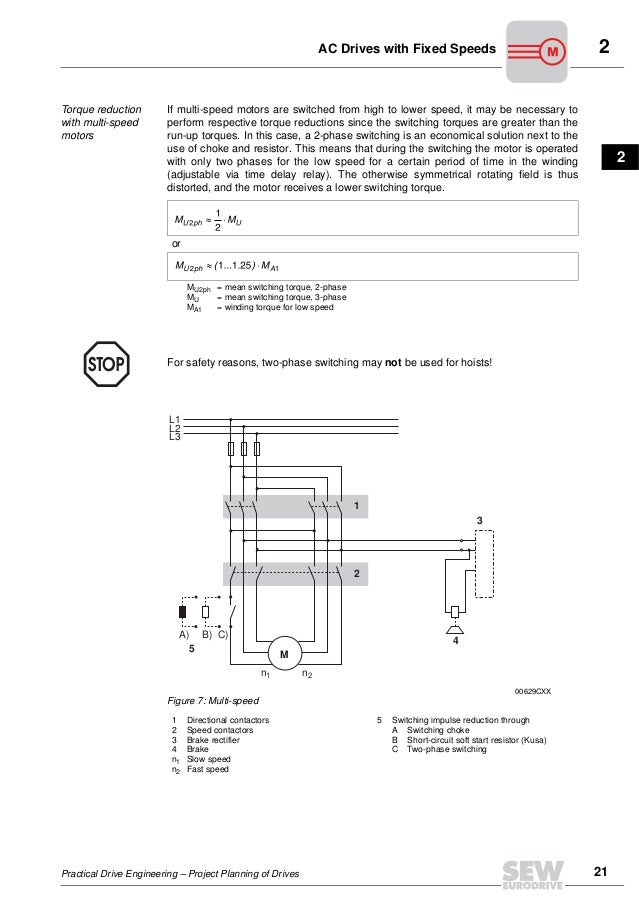

Sew brake rectifier wiring diagram. In addition they may be wired for either normal or rapid stopping. The wiring diagrams for brake connections are located on the inside of the motor conduit box lid. There are certain cases where the brake rectifier can receive its voltage from the motors. Product training 8 brake operation. Connecting wire is to be awg14 mtw 600v 105c temperature rating and black col or. 241 normal starting bg the bg rectifier provides normal starting which is sufficient for most applications with low or infrequent cycling.

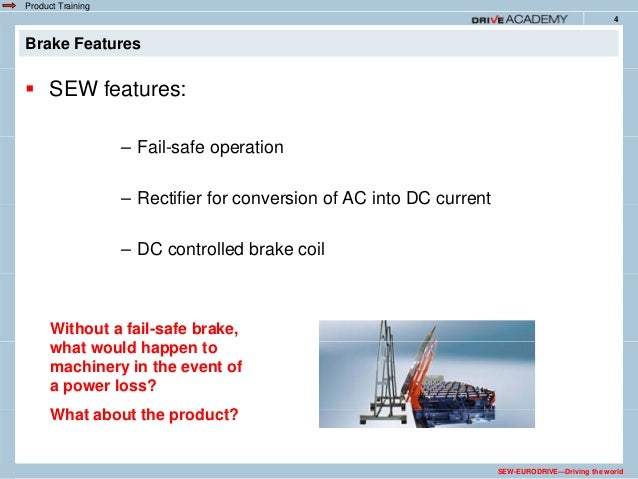

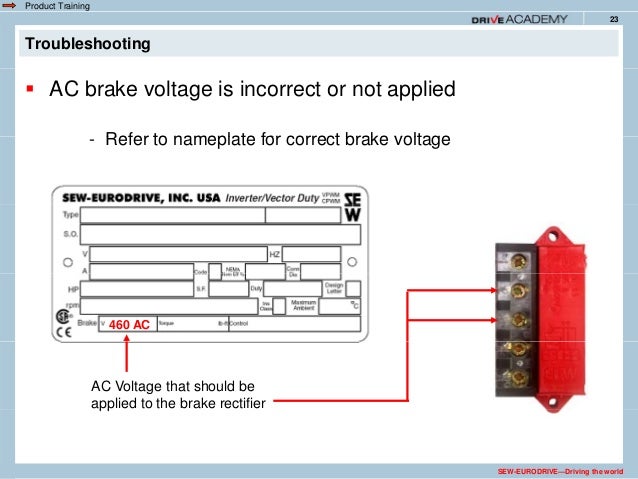

An sew brake rectifier controls both coils. It functions like the rectifier type bge however it is designed to be mounted in a control panel on din rail and not in the motors conduit box. 232 basic functions in contrast to other disc brakes with a dc coil the sew brakes operate with a two coil system. The brake will release and allow the motor to rotate when the nameplate ac brake voltage v b is supplied to the brake rectifier terminals. Product training 23 troubleshooting. The bme brake rectifier is a half wave rectifier with overvoltage protection elements and electronic control for reducing the brake release reaction times.

6 2018 common connection diagrams 24 brake control sew brakes are available for either normal or rapid starting. Refer to the operating instructions for wiringrefer to the operating instructions for wiring diagrams sew eurodrivedriving the world. A characteristic feature of sew brakes is th eir very short length. The integrated design of the sew brake motor makes for particularly compact and sturdy solutions. The brake endshield is a part of both the motor and the brake. The recommended ring terminals are manufactured by thomas betts or equivalent.

)/images/TechNote/TechNote.gif)